Interview with Radhika Bharathi

This interview is part of a series which highlights the work of various individuals and organizations within the Kernza® network. Through these interviews, we aim to share and celebrate that there is a large and ever-changing ecosystem that moves Kernza® perennial grain forward. If you would like your organization’s work to be featured in an interview, please email Sophia Skelly. To learn more about the Kernza® network, visit our directory.

Can you introduce yourself and tell me a little about your research with Kernza®?

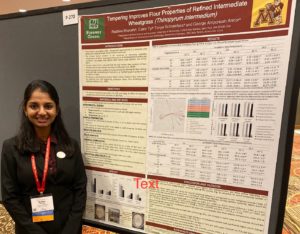

My name is Radhika Bharathi and I’m a Ph.D. student at the University of Minnesota. I have a bachelor’s degree in chemical technology and then my master’s right now is Food Science with a focus on cereal chemistry. My advisor George Annor worked with the Forever Green Partnership before I started in his lab. He had done some projects with them before and I think I met Kernza® just by destiny. I’ve personally been very interested in sustainability ever since I was a child. I’m also a vegetarian and a big follower of recycling and zero waste lifestyle. So I think that Kernza® and what it stands for fits very well with my values and I feel very fortunate to be associated with sustainability. Moving on in my career, I want to contribute towards fields that develop sustainable, healthy food products.

Did you hear about Kernza® from your advisor?

Yes, but I think the first time I actually learnt about Kernza® in detail was from a graduate student in a seminar in my department. He was working on storage stability of Kernza®. He basically made tortillas and was describing qualitative stable analysis done for Kernza® and how storage stability and the addition of bran affects Kernza®’s taste or the taste of tortillas made from Kernza® flour. That is when I really understood that there are so many aspects to Kernza® and there is so much that can be done with this valuable crop!

Can you talk a little bit about your work with tempering for people who may not be familiar with how food science works?

Yes, for sure. So my project is about tempering Intermediate Wheatgrass, or Kernza®. So what tempering basically means is that before milling, you add a certain amount of water and that moisture seeps to different layers in the grain and it softens the endosperm and it toughens the bran. So imagine peeling off an orange: the harder the skin, the easier it is to peel it off. Basically, adding moisture toughens the outer bran so it facilitates better separation of the inner endosperm from the outer bran. At the end of all of this you get better, refined flour.

So the other question I often get is: “OK, but why do you want to refine Kernza® if all the goodness lies in the bran?” And the answer is that bran is good for health but when it comes to functionality, bran particles are notorious because they steal water from gluten; they hinder gluten formation. My colleagues at the University of Minnesota from a different lab did an experiment where they used dough conditioners to enhance properties of bread made from Kernza® and they noticed that the effects of dough conditioners were the best when Bran was removed. They also made bread by changing the percent of bran in Kernza®. For example, they made breads with 0, 50, and 100 % bran.

They noticed that the breads that had zero percent bran had the highest scores in “low volume” and the best physical attributes for bread. So all of their previous work indicated that refining is a viable processing option in terms of functionality for Kernza® and bread is the most common model system or the most common cereal product that all consumers eat. And if Kernza® were to become a mainstream ingredient, we would typically want Kernza® to perform well in a bread model system. And we think that that is possible by refining Kernza®.

Essentially, refining helps, and you refine better by tempering. All traditional grains–wheat, for example–have a tempering condition established. Nothing like that has been established yet for Kernza®.

Can you talk a little bit more about the gluten formation? Once Kernza® is tempered, is it able to build stronger gluten?

Yes, it is. That has been one of the most exciting results from my studies. If we compare a non-tempered control to a tempered flour, we see that due to tempering, we are effectively removing all of the bran. This means the gluten proteins have less competition and it gives rise to stronger gluten networks in tempered flours. We’ve analyzed it quantitatively using a GlutoPeak. That’s the machine that we use to measure gluten aggregation.

How does that machine work?

The GlutoPeak is super cool. It’s a standard rapid test machine that is used in the cereal field to measure gluten aggregation. And in the machine, you basically add about eight grams of flour, depending on the moisture content. You first take the moisture content, you enter it in the machine and it’ll tell you to add somewhere around eight to 10 grams of flour and then you add calcium chloride.

So if you were to do this in your house, you would take flour, you would add water and then you would knead the dough. The machine does something similar. But instead of using water, you add calcium chloride because calcium ions help in stabilizing the gluten network. The machine has a paddle that goes inside the container and it kneads the dough and yields a graph! As gluten is being formed, the machine measures the sheer force and you get an increasing graph. When the dough has been formed to the maximum, the machine still keeps mixing and the sheer force of the machine exceeds the strength of the gluten and it starts breaking the gluten bonds which is shown with a downward fall in the graph.

Have you been involved with the Cooking with Kernza® civic science work? To what extent does your research connect with folks who are working on recipe development?

I know that my advisor collaborates with Beth Dooley and they talk about future product development opportunities for Kernza®. I personally haven’t been involved in any kind of education for Kernza® crops. I have been in touch with Connie Carlson worked with her as an “Applied Research and Marketing Intern.” It was on a volunteer basis but I learned some really cool things and that was a very good exposure to the civic engagement side of Kernza® for me.

Many civic science participants noted that the Kernza® flour didn’t rise as well as other flours. Is that related to tempering?

I feel like tempering will definitely help you to bake better-looking bread in terms of loaf volume, but Kernza® inherently has a different gluten profile compared to wheat. So in order to have a great-looking bread, you have to have two components of gluten: one is called glutenin and one is called gliadin. Glutenins are the molecules that give you the dough-raising properties and gliadin give you the elasticity. Kernza® has a lot of gliadin but has less glutenin, so breads made with Kernza® don’t rise as well. I think that is one of the reasons Kernza® bread is different from wheat bread. Kernza® is also very sticky and it kind of reminds me of rye. Kernza® is a cousin to both wheat and rye and I feel like it’s somewhere in-between. It has properties of both.

Yes, there were many civic science participants who compared it to rye as well. They also compared it to wheat bran.

Yeah, it’s very sticky. I can see why people have complaints about workability around Kernza®. We haven’t yet really narrowed down to what exactly makes Kernza® dough sticky. It could be the fiber; it could be that we are adding too much water.

What is your favorite part of researching Kernza®?

My favorite part about researching Kernza® is the endless opportunities we have with this awesome perennial grain. I feel like Kernza® is the new kid on the block and there are so many cereal processing technologies that you could use to improve Kernza®’s functionality and tempering is just one of them. My advisor is looking into optimizing sprouting conditions and using sprouting as a technique to make bread healthier because it makes nutrients more bioavailable.

The other thing is puffing. And all of these other cereal processing technologies that exist and can be applied to Kernza® are very exciting because they help to expand Kernza®’s portfolio in different products. So beyond bread, can we have popped Kernza®? Puffed Kernza®? Kernza® waffles? Kernza® muffins? I find that very exciting because there is so much we can do with this grain and there’s so much not yet explored. This is especially true when it comes to nutrition. We know that Kernza® has higher antioxidants but it would be cool to see if they are equally absorbed in the body like wheat–maybe they’re better absorbed!

The other thing that really excites me is whenever I present my research, I get endless questions and there’s so much excitement. I recently presented at a conference, and the questions I got were less technical and more about consumer enthusiasm and taste. I truly enjoy applied food science research and Kernza® fits into that perfectly. It’s a good blend of applied and analytical chemistry and product development opportunities. It gives you a satisfaction of working on something you can directly present to the consumer. I’ve worked on previous projects, especially with chemistry in my undergrad where I would present and people would just be like, “Why does it matter?” It’s very difficult to explain science to a diverse audience but I feel like every time I do that with Kernza®, it connects with people. They understand it and they’re excited to try it as a new grain.

What is your favorite thing to cook with Kernza®?

Pancakes! I first tried Kernza® pancakes at Birchwood Cafe and I absolutely loved them. They have a very unique, earthy, but also nutty, grassy flavor. And then I recently tried making my own pancakes at home. It was a 50/50 mix of Kernza® and whole wheat and they turned out to be delicious.

Do you have any specific plans or aspirations related to Kernza® going forward?

My immediate goal postgraduate school is to work in product development positions in the food industry to gain more exposure and experience in that area. In the long run, it is my dream to start my own company to manufacture nutritious, healthy and sustainable cereal-based products from climate-friendly grains such as Kernza®!

Is there anything I haven’t asked that you would like to share?

I took part in a “lightning talk competition” on sustainability and the environment at our university and I won the first prize for my lightning talk on Kernza®! You can watch it here: https://www.youtube.com/watch?v=zgp4NBIpdrg (timestap 12:25)